Solar reflective finish sc 10 sr tan meets california title 24 requirements helps reduce the urban heat island effect lowers the surface temperature icc evaluated esr 2201 meets class a fire test astm e 108 meets one hour fire rating astm e 119 meets class i vapor retarder astm.

Reinforced expoxy roof membrane.

Pvc roofs are specifically engineered for strength ensuring the membrane s long service life.

Advanced solid phase polymer formulation.

The rubbergard max epdm membrane is an internally reinforced cured single ply roofing membrane that is designed to combat roof tears and punctures and provides superior resistance to wind forces.

Similar to a fabric reinforced roof a coating membrane can be applied to any surface.

Its main color is white.

Aramid fiber is woven into the fastening side of all full rolls of pvc membrane.

Simply called roof coating it comes in a liquid form and adheres fully to your existing roof.

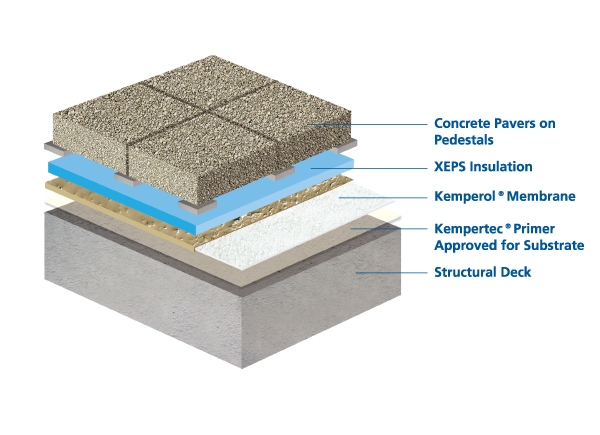

Flat roof decks observation decks various other deck coatings and balconies on commercial and residential buildings carrying pedestrian traffic.

Solar reflective finish sc 10 sr gray crrc product id 1316 0002.

Weather deck has been approved as a class a fire retardant roofing system by.

This flexible resilient and elastomeric epoxy roof coating is fully reinforced with a durable stitch bond non woven fabric perfect for all flashing and roofing applications.

About 10 common roofing problems to watch out for.

Internally reinforced epdm membrane is ideal for either fully adhered or mechanically attached roofing systems.

Meets the requirements of astm d 4434 type iii.

Our epoxy roof coating system is safe to handle and requires no specialized equipment to install.

This includes a 3 ply built up roof system black epdm modified bitumen and even metal.

Icc es report no.

Sarnafil g series membranes are the first fiberglass reinforced single ply membrane in the industry specifically designed for adhered and loose laid systems they deliver exceptional dimensional stability and a low coefficient of thermal expansion and contraction to extend the service life of the roof.

The american society of testing and materials astm requires a roofing membrane to have a minimum breaking strength of 200 pounds per inch.

Uses the optimal amount of dupont elvaloy kee ketone ethylene ester polymer to ensure plasticizer retention extend roof life and reduce maintenance costs.

Pvc roofing membranes far surpass this standard all having a minimum breaking strength of 350 pounds per inch.

Crrc product id 1316 0001.